In the complex world of industrial automation and process control, efficiency, reliability, and flexibility are paramount. The Control Engineering Application Software Platform (CEASP) acts as a sophisticated digital brain, orchestrating complex operations across countless industries. These platforms are far more than simple programming environments; they are comprehensive ecosystems integrating design, real-time execution, monitoring, data management, and security. For engineers, project managers, and operations professionals, understanding their capabilities and diverse application scenarios is key to achieving operational excellence and driving innovation.

The UWNTEK Control Engineering Application Software Platform embodies the cutting-edge technology in control engineering software. We prioritize robustness and versatility, integrating numerous key capabilities into a unified environment:

Multi-platform execution: Runs seamlessly across Windows environments and other heterogeneous systems.

Real-time control: Executes complex control algorithms with precise timing.

Graphical monitoring: Provides intuitive, real-time process visualization.

Extensive historical database: Securely stores and manages vast amounts of operational data for analysis.

Comprehensive security: Implements robust alarm management, safety interlocks, and operational event logging.

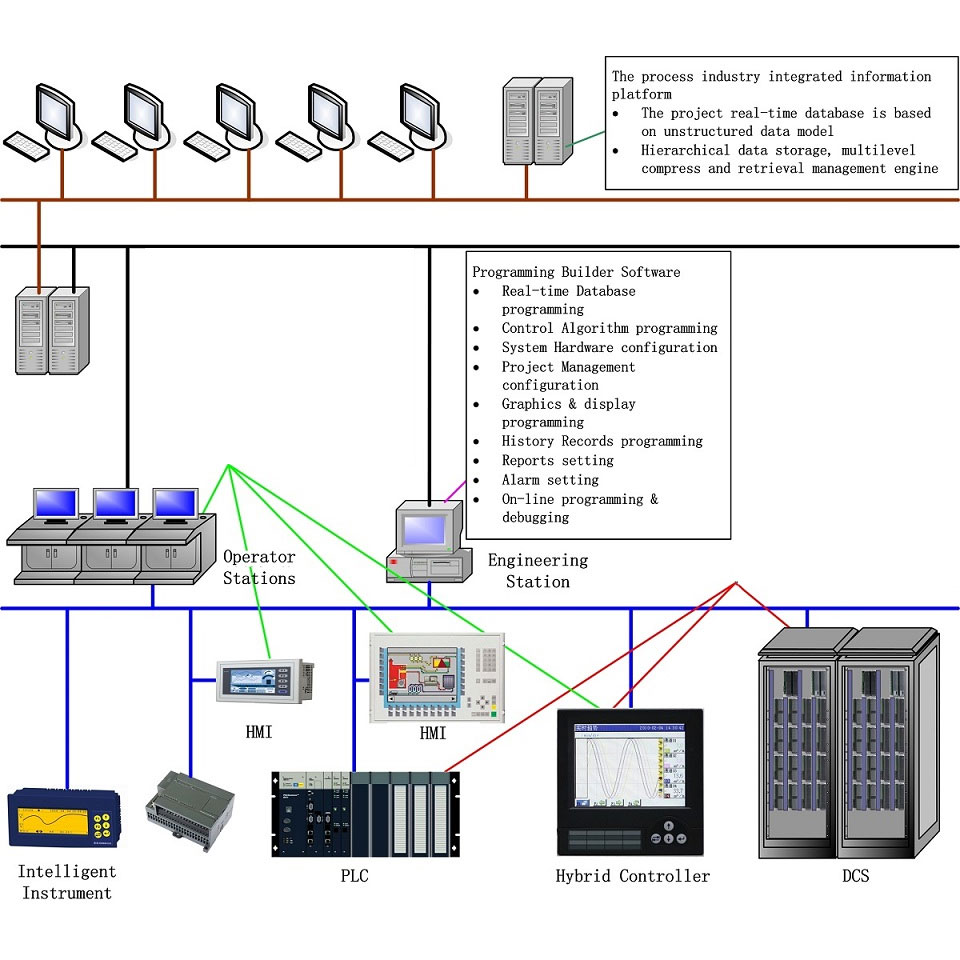

Unified environment: Integrates engineering, configuration, operator visualization, and real-time control. Distributed Architecture: Engineering, operator, and field control station software run on the corresponding hardware layers (WS/OS/FCS) and communicate seamlessly over control and system networks.

| Feature Category | Description |

| Multi-Domain Modeling | Builds control systems using reusable models (static/dynamic, process data), methods (control/optimization algorithms), and display interfaces. Enables "building" equipment models and programs via reuse and reconstruction. Abstracts data, functions, and graphics for intuitive, efficient engineering. |

| Real-Time Data Quality Stamps | Identifies data quality status (channel faults, sampling deviations, range overruns, network status, hardware redundancy). Ensures reliable, available data for secure decision-making. Supports historical recording and analysis of values and quality stamps. |

| Distributed Algorithm Scheduling & IEC 61131-3 | Employs data-driven, event-triggered scheduling. Supports graphical (FBD, LD, SFC) and textual (ST, IL) programming per IEC 61131-3 standard. Facilitates logic, motion, and process control integration. Enables algorithm encapsulation, reuse, offline configuration, online configuration, simulation, and debugging. |

| Open Communication & Real-Time Database | Implements drivers (Modbus, ProfibusDP) and OPC interfaces. Uses transparent network management for third-party device integration. Builds a distributed real-time database with globally consistent interfaces for multi-real-time, multi-semantic data integration. |

| Precision Time Synchronization | Utilizes GPS via NTP protocol to synchronize clocks across all control and operator stations. Enables accurate Sequence of Events (SOE) recording and unified time-stamping for all data logging. |

| Expandable Industry Algorithm Library | Provides a customizable core library refined with expert knowledge. Released as industry-specific algorithm packages for easy loading and immediate application. Based on reusable/reconfigurable architecture and unified modeling, significantly boosting engineering efficiency. |

| SA-S88 Batch Control & Formula Management | Implements ISA-S88 standards for decomposing processes, standardizing logic, and equipment module packaging. Separates control and process engineering roles. Encrypts critical batch recipes and parameters. Enhances safety, prevents errors (leaks, contamination, wrong operations), improves efficiency/equipment utilization. Ideal for multi-variety, multi-batch process industries. |

| Engineering Productivity Tools | Remote Update: Allows configuration changes without on-site visits. Collaborative Configuration: Enables multi-engineer synchronous work on large projects. As-Built Drawing Export: Generates detailed project documentation post-commissioning. |

| Advanced Visualization & HMI | Rich Device Library: Simplifies HMI screen creation and modification. Header/Footer Templates: Similar to PowerPoint, ensures consistent yet customizable screen styles. Web-Based Remote Access: Provides installation-free browser access to process screens with strict user authentication. |

| Alarm & Security Management | Flexible Alarm Sound System: Configurable sounds aligned with alarm groups and levels. Functional & Security Areas: Granular user permissions tied to roles, safeguarding project integrity and operational safety. |

Q: What specific features of the Control Engineering Application Software Platform support these diverse application scenarios?

A: Versatility stems from the following core capabilities:

Multi-Domain Modeling and Reuse: Allows pre-built and reused complex equipment or process unit models (pumps, reactors, conveyors), significantly accelerating the engineering of repetitive or similar applications across different plants or product lines.

IEC 61131-3 and Advanced Scheduling: Provides programming flexibility, enabling implementations ranging from simple ladder logic for machine safeguarding to sophisticated model predictive control (MPC) for process optimization, to complex state-based sequences for batch production. Data-driven, event-triggered scheduling ensures deterministic execution, which is critical for motion control and safety interlocks.

Powerful Data Processing and Integration: A quality-stamped, real-time database ensures the reliability of control and analytical data. Open communication standards (OPC, Modbus, Profibus) enable seamless integration with a wide range of sensors, actuators, PLCs, and existing factory systems (MES, ERP), making the platform ideal for brownfield upgrades and heterogeneous environments.

Batch and Recipe Management (S88): This is critical for industries such as pharmaceuticals, food and beverage, and specialty chemicals. The platform supports defining complex recipes, managing equipment phases, enforcing safety procedures, ensuring batch traceability, and preventing operator errors—critical for quality, compliance (GMP, FDA), and flexible production.

Scalability and Remote Management: The architecture is scalable from small, standalone devices to large, distributed, plant-wide systems. Remote engineering updates and web-based HMI access significantly reduce downtime and the costs associated with on-site support and troubleshooting.

Q: How does UWNTEK address niche or advanced application needs?

A: UWNTEK includes the following features to address specific, complex challenges:

High-precision synchronization (GPS/NTP): Critical for applications requiring precise event sequencing across distributed systems, such as power grid fault detection/isolation (SOE) or coordinating high-speed production lines across large areas.

Collaborative engineering and as-built documentation: Essential for managing large projects (e.g., power plants, refineries) with multiple engineering teams working simultaneously, ensuring consistency and producing accurate final documentation for regulatory compliance and maintenance purposes.

Enhanced safety and security: Fine-grained security zones and functional areas prevent unauthorized access or manipulation. Combined with robust alarm management and S88 procedural control, this reduces risk in hazardous processes or high-value production environments. Remote web access includes strict authentication protocols.

Specialized industry libraries: Pre-packaged algorithm libraries tailored to specific industries (e.g., specific reactor models for chemicals, packaging machine logic for food and beverages) accelerate deployment and embed industry best practices directly into the platform.